Lisebelisoa tsa ho lokisa starch ea litapole ke lisebelisoa tsa ho lokisa starch ea litapole tse monate, lisebelisoa tsa ts'ebetso ea theknoloji ea ho sebetsa ke:

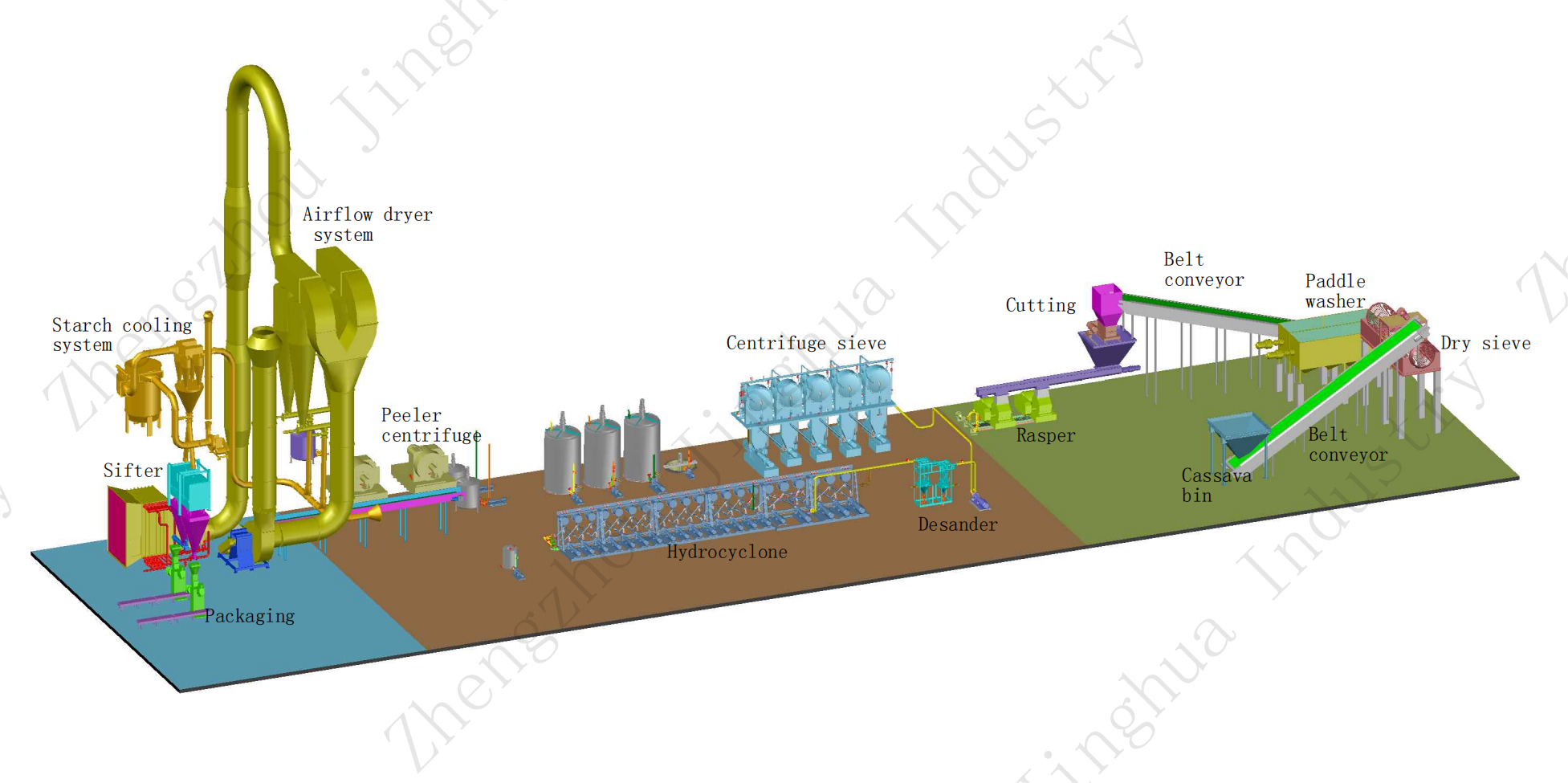

Litapole → (ho hloekisa conveyor) → ho hloekisa (ho hloekisa cage) → ho pshatla (hamore leloala) → karohano ea makhapetla le slag (sekirine sa khatello ea curve kapa skrine ea centrifugal, sekirini sa karohano ea pulp le slag) → desander (desander) → karohano ea liprotheine, → karohano ea liprotheine, → (centrifuge kapa vacuum dehydrator) → ho omisa (mohatsela o tlase oa moea o phallang khahlano le se omisang starch) → Ho paka polokelong.

Khetho ea lisebelisoa tsa ho lokisa starch e ka ba ka mokhoa oa ho lokisa starch, matla a ho lokisa lisebelisoa, lisebelisoa tsa thepa, boemo ba starch bo felileng le likarolo tse ling, li kopantsoe le litlhoko tsa bona tsa ts'ebetso, khetha tlhophiso e fapaneng ea lisebelisoa tsa ho lokisa starch. Karolong ea ho sila, baenjiniere ba Kaifeng Sida ba qapile ka ho khetheha mofuta o phahameng oa shredder ea litapole tse monate, ba sebelisa "mochini o sehang + crusher + crusher" theknoloji ea ho sila habeli, coefficient e phahameng ea ho sila, sekhahla sa ho sila thepa e tala ho fihla ho 95%, sekhahla se phahameng sa ho ntšoa ha starch.

Khetho ea lisebelisoa tsa ho lokisa starch e ka ba ka mokhoa oa ho lokisa starch, matla a ho lokisa lisebelisoa, lisebelisoa tsa thepa, boemo ba starch bo felileng le likarolo tse ling, li kopantsoe le litlhoko tsa bona tsa ts'ebetso, khetha tlhophiso e fapaneng ea lisebelisoa tsa ho lokisa starch. Ka mohlala, karolong e senyang, baenjiniere ba Jinrui ba qapile ka ho khetheha mofuta o phahameng oa grinder ea starch ea litapole, ba sebelisa "mochine oa ho itšeha + ho sila" theknoloji ea ho sila habeli, coefficient ea ho sila lintho tse bonahalang e phahame, tekanyo ea ho senya thepa e tala ho fihlela ho 94%, tekanyo e phahameng ea ho ntša starch. Haeba boleng ba starch e phethiloeng ha bo phahame, u ka boela ua khetha mofuta o tlaase oa ho senya hamore.

Nako ea poso: May-26-2023